Rapid Prototyping Manchester

3d Printing Prototype

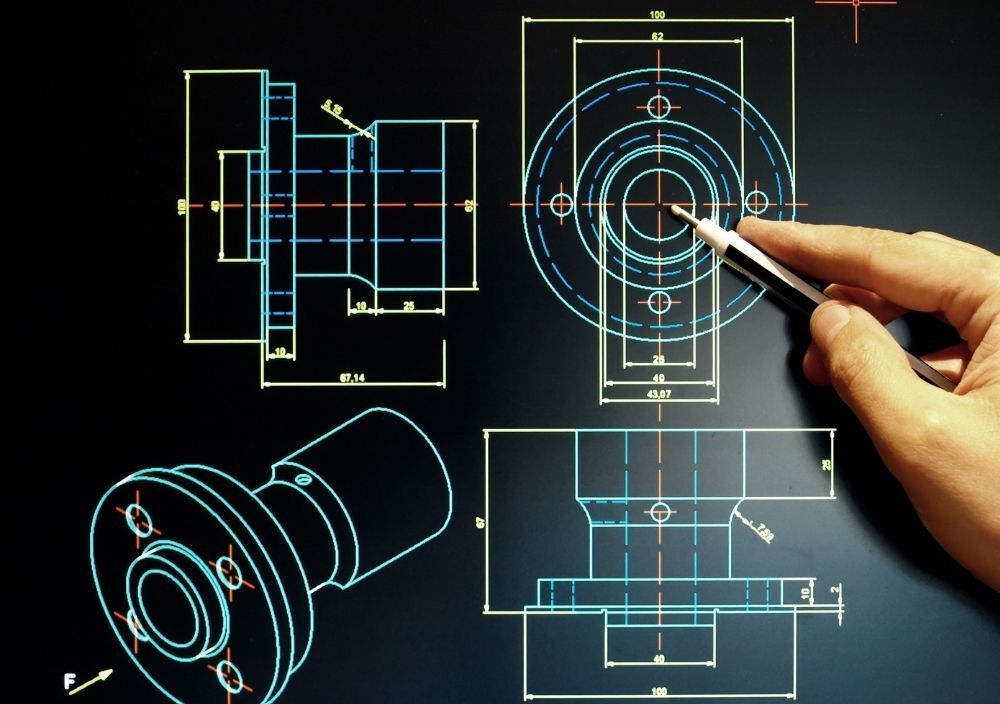

One of our 3D printing services we provide includes Rapid Prototyping. Rapid Prototyping is a term associated with 3D printing as a manufacturing technique, that allows us to create a fast fabrication of parts designed with 3D computer aided design (CAD) software.

We use this service to create a wide variety of industrial products for machine parts, ranging from washing machine to car manufacturers. Or alternatively is you are in a hurry to test a new adaptive we at 3D printing Manchester, can help your ideas manifest into realization at a fast rate. With the help of this technique we can create functioning prototypes, shortening the design time, leading towards successful final products. Here at 3D Printing Manchester, we employ a different rapid prototyping techniques or principles: Additive and Subtractive.

Contact Us 24/7

Subtractive Rapid Prototyping

In the subtractive type of rapid prototyping, we remove material from a larger-solid piece of material until the desired design functionality remains. This process gives us the freedom to design, prototype, and manufacture end-use materials. We use it for parts of small and large volume production runs, so we can obtain specific finishes or specific mechanical properties.

When we are handling this process, we work with resins or metal materials. Depending on our application of choice, we can adjust our design to the material for strength, flexibility, chemical resistance, and other critical characteristics.

This technique is also known as

Generative Design.

Additive Rapid Prototyping

It's the exact opposite of the subtractive type process that additive rapid prototyping operates. Here, instead of removing material, our material is added layer upon layer to build up the specific design such as stereolithography, fused deposition modelling (FDM), and a 3D printing model is created.

Generative Design for Rapid Prototyping

With generative design, we've been enabled to create numerous design options by simply re-specifying your requirements and goals, utilising different materials and manufacturing processes. Generative design will automatically produce a ready design, as a starting point or as a final solution.

Rapid Prototyping Services UK

As a result, we create superior 3D designs by interacting with this technology. Employing this technology at 3D printing Manchester, we are constantly bringing innovative products to market in record time. Your product costs will be optimized, thanks to generative design because it can save you money by rooting out over-designed parts or testing many variations of parts. These are designs that, while reliable, may use more materials or complex manufacturing methods than necessary.

Reliability optimized we carry out stress analysis on the generative design to validate the quality and durability of the designs. This saves you costs in manufacturing. At our 3D printing Manchester, our rapid prototyping through the aid of generative design ensures the production of high fidelity prototypes. That is when the proposed finished product matches the client's design requirements very closely. So instead of adding or removing materials after designing, we’d inputted the desired features, tolerances and metrics to the specification of our clients.

Contact us at 3D Printing Service Manchester today, we can provide

rapid prototyping services UK wide and your expertly designed projects that align with your needs.

Need help?

Looking for rapid prototyping services?

Frequently Asked Questions